Why bearings fail quietly before they break

The majority of process engineers have witnessed it occur. Last week, a bearing that appeared to be in good condition suddenly seizes, stopping production and upsetting the schedule. In actuality, bearing failures are rarely sudden. They emit tiny vibration signals that pinpoint the particular issue long before the noise or heat is noticeable. Catching those signals clearly enough to believe them is the difficult part.

Countroll sensors are useful in this situation. They are wireless, small, and designed for industrial settings. They record clean vibration data at the source. Engineers can identify a flaw early on and confidently plan repairs rather than discovering it after it has caused damage.

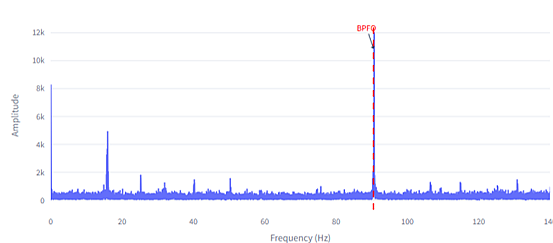

The science behind bearing fault signatures

When a bearing begins to wear, it develops mechanical patterns that show up as precise vibration frequencies. These are not random spikes but repeatable signals tied to the geometry of the bearing itself. Engineers track four main indicators:

BPFO (Ball Pass Frequency, Outer Race) shows outer race damage.

BPFI (Ball Pass Frequency, Inner Race) reflects inner race wear.

FTF (Fundamental Train Frequency) indicates cage or retainer issues.

BSF (Ball Spin Frequency) points to damage on the rolling elements.

Each of these frequencies relates directly to shaft speed and bearing design. As a defect grows, its frequency peak strengthens in the Fast Fourier Transform spectrum, often accompanied by harmonic sidebands. Recognizing those peaks early allows maintenance teams to act before vibration levels reach critical thresholds.

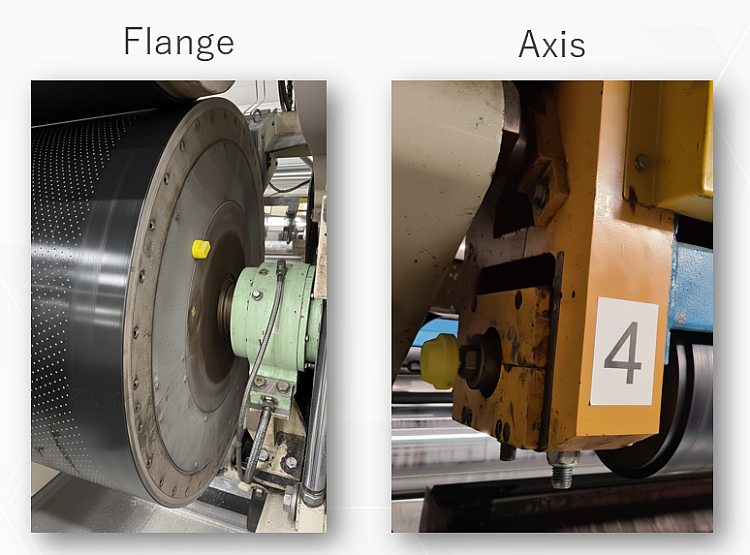

Why sensor placement matters

Where you mount the sensor changes what you see. Bearings transfer vibrations through complex structures, and distance can distort the signal.

Flange-mounted countroll sensors sit right next to the bearing, capturing vibration at its origin. This position delivers a high signal-to-noise ratio and clearer fault frequencies, ideal for tracking BPFO and BPFI patterns.

Axis-mounted sensors read the same fault energy as it travels through the shaft. The data is slightly broader but still precise enough to confirm early bearing wear. Both locations outperform housing-mounted sensors, which tend to filter out higher frequencies.

Clean data from the source means fewer false positives and faster identification of real issues. With wireless transmission and simple installation, countroll makes this precision easy to achieve.

From early detection to real results

In one steel plant, a flange-mounted sensor picked up an outer race defect two weeks before a scheduled shutdown. The maintenance crew replaced the bearing during planned downtime, avoiding a full stoppage and costly secondary damage. In another case, a paper mill identified inner race wear on a drying roll by monitoring a rising BPFI peak trend. The problem was corrected before it affected product quality.

These examples show how early warning is not theory. It is measurable and repeatable when the signal is clean.

Looking ahead

If you are reviewing your vibration monitoring setup or planning a move toward predictive maintenance, it might be worth seeing how countroll sensors fit in. Their small footprint, wireless design, and clear data make them a practical way to strengthen bearing analysis without overhauling existing systems.

You can send us an e-mail on info@countroll.com. The sooner the signals are clear, the sooner maintenance decisions can be made with certainty.